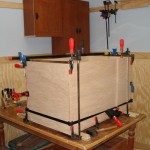

After completing all the dados on the tablesaw yesterday I did a dry fit and clamp of the carcase. Everything looked good, but I decided it was too late to start the glue-up so that would have to wait for the next day.

Tonight I did the finally check for square, dismantled the dry fit and started the glue-up. This took longer than I had expected, but I kept moving at a good pace hoping I would complete it before the glue started to set-up.

I used a waterproof glue (Titebond III) but the setup time is quick so you need to work fast with this many panels to assembly in one shot. The divider also had to be positioned and glued at this point since this wouldn’t be possible after the carcase was assembled. The shelf and sliding tray rails I’ll add later.

Of course I felt that I could use about 10 more clamps to get the joints nice and tight but I made do with what I had. I did purchase a new band clamp and pipe clamp for this job. I could probably use about 2 more band clamps for this assembly.

The glue-up is complete and drying. Next I’ll add the oak trim to the bottom, but before I do that I need to build a miter sled for the table saw so I can cut some perfect 45 degree miters. Stay tuned ……

Add Comment

You must be logged in to post a comment.